Contact us

Contact

Wandy 16B

40-322 Katowice

info@krm-trade.pl

(+48) 796 369 439

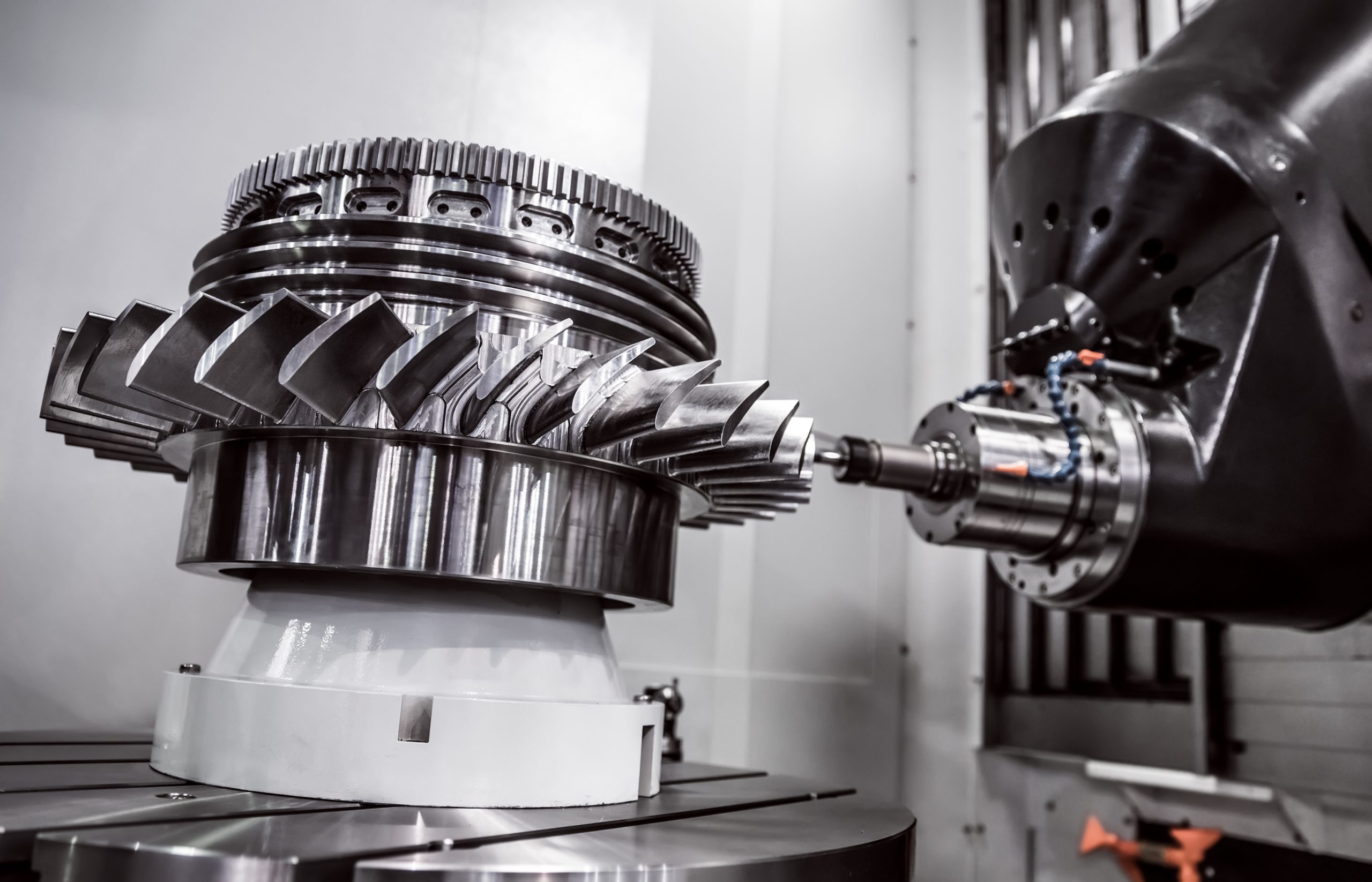

CNC milling

Cutting machine tools have been doing hard work in manufacturing plants for years. Technological progress has resulted in the appearance of a lot of computer-controlled devices. With their help, you can achieve much better results than those obtained using manually set milling machines. Is this the only reason why CNC milling is one of the most popular methods of detail shaping? There are more benefits.

CNC milling - what is it?

CNC milling uses computer-controlled machine tools. Another name is precision or numerical milling, which perfectly reflects the quality of details obtained in this way. The machine tool control system can be freely programmed and adapted to the needs of a specific order.

Precision milling - what is it?

The operator sets the required parameters (tool position, feed rate, coolant on, spindle speed, passes) numerically, and then the computer program converts the request into a specific action. The controller regulates the operation of the milling machine, which consists in machining a stationary object by a milling tool that performs a rotary motion.

The blade of the tool cuts the outer layer of the material until the programmed shape is obtained. Full automation of the process guarantees excellent milling precision.

CNC milling - what is it for?

The use of CNC milling machines is practically unlimited (as long as the technological requirements are met). There is a demand for this type of services in many industries (including advertising, heavy industry). Due to the volume of production, precision milling is used in

Unit production – these are individual orders for unique elements, such as: dies, injection molds, prototypes, stamping dies

Serial production - we are talking about the production of machines. Parts are made by milling. This method of processing gives a lot of freedom in design and saves money.

Mass production – applies to small details and other products where mass production requires optimization of costs and a constant increase in production speed

Numerical milling - advantages

high machining precision;

excellent repeatability of elements with the desired quality;

less material consumption;

perfect mapping of design assumptions;

universality of applications;

easy to adapt the production line

We use top-class equipment whose algorithms have been written in such a way as to ensure maximum efficiency without sacrificing quality.